Or, "Looking in the mirror at a Bonehead" Part Two, The Rest of the story...

It is with some trepidation that I write this, but if we can stand peer review then we probably should hang up our headsets.... This is a long story, but i will try to do the short version..... So here it is....

In light of the Mirror story, I wanted to get some time on the Rocket in anticipation of a trip that would have taken me from Iowa to West TX then CenTex, then home, this weekend. So Wednesday evening I took off to do some flying.

I also needed to do some acro to get warmed up for the summer show season.... I was about 15 miles from the airport at an area over a farm strip where I sometimes practice. I like to practice over or near a runway.... I made a low pass to inspect the condition of the runway after the recent snow melt and to notify the farmer that I was in the area. He likes to watch...

As I was pulling up off the low pass, I started adding power and the engine stumbled. It was running, but not right. It would not accept throttle without dying. Pulling the power back smoothed it out. I did all the standard stuff, switched tanks, boost pump on, mags, fooled with the mixture, but the fuel flow was about 6 gallons per hour and nothing changed that. I could climb at that fuel flow so I climbed higher over the strip and pondered my options... I was somewhat concerned that the strip might be soft, and I wanted to get home, but it was a long 15 miles to the airport so I landed. The farmer came out and we pulled the line from the fuel servo, turned on the boost pumps and both tanks ran a full stream of fuel.... I pulled the finger screen out of the servo and it appeared perfectly clean....

I hooked the line back up, fired up the airplane and it ran fine.... Now what??? I called my Mechanic and we chatted for a while.... We talked about unporting a fuel tank because of a hung up flop tube... Maybe it was airlocked.... (I did not buy that) I decided that I would run it some more and if it made power for a significant period of time, I would launch and fly home over a 4 lane divided highway that went directly to the airport without much traffic at all.

Rightly or wrongly, I took off. Even when it was acting up, it would make enough power to maintain flight, so I took off and it ran perfectly. I climbed way up high and it purred all the way home... On the way I decided I would try to duplicate the event, so over the airport, Left tank, low power, steep descent at high speed.

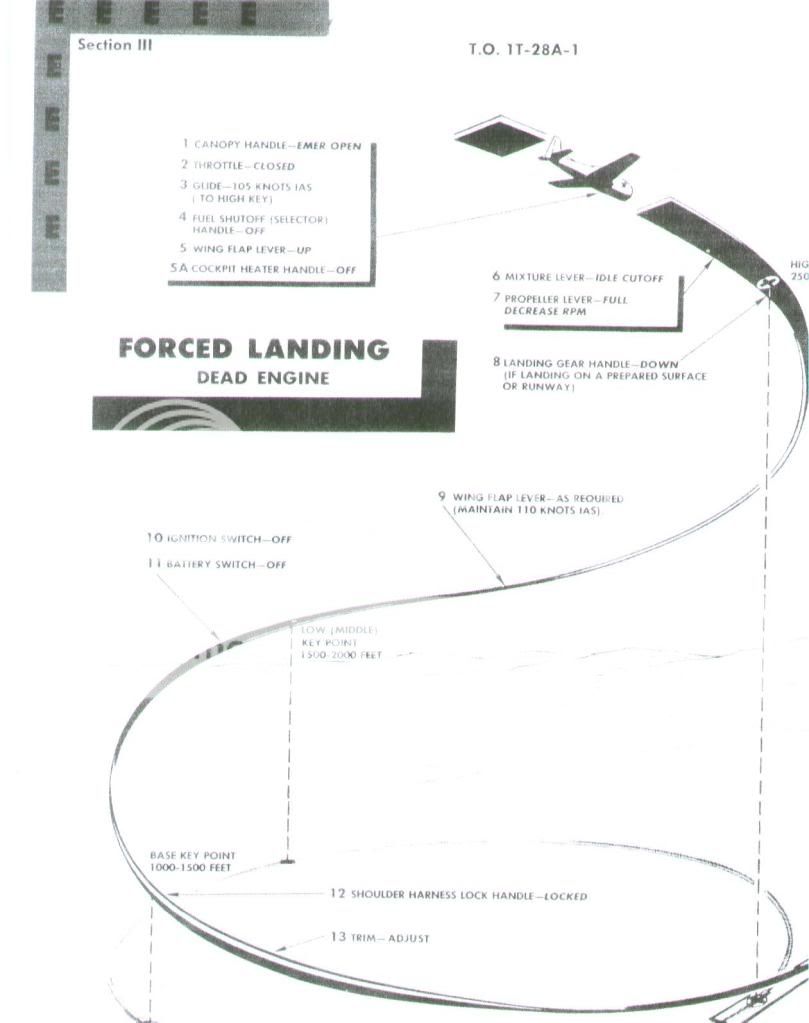

After about a 3000 ft descent I added power, and again, it stumbled and again, it would not take power.... Again, I tried everything I could think of, but nothing made a difference. I took the opportunity to practice a deadstick landing. I pulled the power back, hit the high key, bent it around and landed exactly on the fixed distance marker and taxied in... I let the airplane sit for a bit, went out fired it up and it ran perfectly..... Hmmm??? I went home and I called another mechanic,

This mechanic said it was possible to ice up the Venturi in an injector servo and that will shut off the air signal in the servo diaphagm and it will only deliver the idle circuit fuel.... The next morning I called Don Rivera at Air Flow Performance. He was perplexed. He said it could be ice, but he doubted it. He did say if it was ice it could do what I described. He wanted me pull it off and send it in,.... I don't like sending things in when I don't know whats wrong with them, especially when it could be something else.... I like to find the problem so that I can know I have fixed it.

The ice was the best explaination I had heard so far. The evening before it was cold and high humidity. This made sense as to why it would run after being shut off.

The next morning a high pressure had come thru and cleaned up the humidity. I looked everything over again, buttoned it up, fired it up, went to the long runway and took off...

Now before anyone says I am totally crazy, The way our airport is laid out, there is no time on a 18 departure in the Rocket where I dont have a good option.

I climbed up to 8000 ft over the airport, it ran great. I tried several low power, steep descents for nearly half an hour. It ran perfectly..... "It must have been the ice"

As sure as I was that it was ice, it was with some trepidation I loaded up my stuff and headed for Texas.

I have several airport options after departure. It was severe clear all the way to TX, so I filed for 16,000 feet and away I went. At 16,000 there is no place between MCW and my fuel stop in Wichita where I did not have an airport within gliding range.

It was running great and I was pretty well convinced that ice was the culprit, until about 15,500. The EGTs started climbing and got rough. I told ATC that i wanted to return home. Again i tried everything, but the fuel flow kept slowly dropping and I realized that getting back to Mason City would be tight. By then I was almost directly over Belmond. I had 3 or 4 airports within range at that point, but i chose the one below me.

I told ATC that I would cancel and land. They asked me relay through another airplane to them when I safely on the ground.

It is a long trip from 16,000 to the surface. I had lots of time to kill so I tried everything to identify the problem... No luck... it would not deliver more fuel. The fuel flow was below 3 gallons and really could barely tell the difference between the mixture forward or idle cut-off. I pulled the prop back and spiraled down over the airport.

The actual landing was a non-event. I was over the high key at 1800 AGL, did my 360 and when i had the airport made, pushed the prop up, dumped the flaps and slipped like a big dog to a landing just past my aim point on the runway.

The engine was idling, but advancing the throttle at all would kill it. I radioed to an over-flying airplane to tell center that I was safely on the ground....

It would not taxi in the grass. I pulled the mixture, it quit, I pushed the throttle up and hit the boost pump, the fuel flow went to 8 gph. I hit the starter and it fired up, ran fine and I taxied in....

I was done trying to diagnose the problem.... The servo is on the way to Air Flow Performance. I have pulled all the hoses in the fuel system. They all look good, but I will replace them because it's time. I still have no idea why it would not run...

Some will disagree with my descision to fly it to diagnose the problem. I can accept that. I can argue that after the first take-off from the farm strip, I was never in a place where I did not have a good landing option. I can argue that at that point I believed, even when it was not working, it would deliver enough fuel to fly. Still it would be pretty easy to argue that I should not have taken off from the farm strip. That is a fair criticism...

As for what is causing the problem? I am totally stumped. I hope Don finds something, or the next take-off will be no fun at all....

It may end up being connected with the painting (I hope) because the airplane was dormant or the dust in a paint shop.

If paint dust proves to be the culprit, that is pretty scary.... It could have been several more hours before the problem arose.

There is room to discuss whether I should have tried to find the problem by flying, but what this really highlights is how stupid it was to fly it home from the paint shop and land in low IMC. That flight was the flight before this problem surfaced. Had the engine started losing fuel flow in Low IMC it could have been a very different outcome.

No matter what altitude, a dead stick to a 2-300 foot ceiling is a bad deal. Even if you are directly over an airport.

I will file a report when (& if) I figure out what the problem is.....

It is with some trepidation that I write this, but if we can stand peer review then we probably should hang up our headsets.... This is a long story, but i will try to do the short version..... So here it is....

In light of the Mirror story, I wanted to get some time on the Rocket in anticipation of a trip that would have taken me from Iowa to West TX then CenTex, then home, this weekend. So Wednesday evening I took off to do some flying.

I also needed to do some acro to get warmed up for the summer show season.... I was about 15 miles from the airport at an area over a farm strip where I sometimes practice. I like to practice over or near a runway.... I made a low pass to inspect the condition of the runway after the recent snow melt and to notify the farmer that I was in the area. He likes to watch...

As I was pulling up off the low pass, I started adding power and the engine stumbled. It was running, but not right. It would not accept throttle without dying. Pulling the power back smoothed it out. I did all the standard stuff, switched tanks, boost pump on, mags, fooled with the mixture, but the fuel flow was about 6 gallons per hour and nothing changed that. I could climb at that fuel flow so I climbed higher over the strip and pondered my options... I was somewhat concerned that the strip might be soft, and I wanted to get home, but it was a long 15 miles to the airport so I landed. The farmer came out and we pulled the line from the fuel servo, turned on the boost pumps and both tanks ran a full stream of fuel.... I pulled the finger screen out of the servo and it appeared perfectly clean....

I hooked the line back up, fired up the airplane and it ran fine.... Now what??? I called my Mechanic and we chatted for a while.... We talked about unporting a fuel tank because of a hung up flop tube... Maybe it was airlocked.... (I did not buy that) I decided that I would run it some more and if it made power for a significant period of time, I would launch and fly home over a 4 lane divided highway that went directly to the airport without much traffic at all.

Rightly or wrongly, I took off. Even when it was acting up, it would make enough power to maintain flight, so I took off and it ran perfectly. I climbed way up high and it purred all the way home... On the way I decided I would try to duplicate the event, so over the airport, Left tank, low power, steep descent at high speed.

After about a 3000 ft descent I added power, and again, it stumbled and again, it would not take power.... Again, I tried everything I could think of, but nothing made a difference. I took the opportunity to practice a deadstick landing. I pulled the power back, hit the high key, bent it around and landed exactly on the fixed distance marker and taxied in... I let the airplane sit for a bit, went out fired it up and it ran perfectly..... Hmmm??? I went home and I called another mechanic,

This mechanic said it was possible to ice up the Venturi in an injector servo and that will shut off the air signal in the servo diaphagm and it will only deliver the idle circuit fuel.... The next morning I called Don Rivera at Air Flow Performance. He was perplexed. He said it could be ice, but he doubted it. He did say if it was ice it could do what I described. He wanted me pull it off and send it in,.... I don't like sending things in when I don't know whats wrong with them, especially when it could be something else.... I like to find the problem so that I can know I have fixed it.

The ice was the best explaination I had heard so far. The evening before it was cold and high humidity. This made sense as to why it would run after being shut off.

The next morning a high pressure had come thru and cleaned up the humidity. I looked everything over again, buttoned it up, fired it up, went to the long runway and took off...

Now before anyone says I am totally crazy, The way our airport is laid out, there is no time on a 18 departure in the Rocket where I dont have a good option.

I climbed up to 8000 ft over the airport, it ran great. I tried several low power, steep descents for nearly half an hour. It ran perfectly..... "It must have been the ice"

As sure as I was that it was ice, it was with some trepidation I loaded up my stuff and headed for Texas.

I have several airport options after departure. It was severe clear all the way to TX, so I filed for 16,000 feet and away I went. At 16,000 there is no place between MCW and my fuel stop in Wichita where I did not have an airport within gliding range.

It was running great and I was pretty well convinced that ice was the culprit, until about 15,500. The EGTs started climbing and got rough. I told ATC that i wanted to return home. Again i tried everything, but the fuel flow kept slowly dropping and I realized that getting back to Mason City would be tight. By then I was almost directly over Belmond. I had 3 or 4 airports within range at that point, but i chose the one below me.

I told ATC that I would cancel and land. They asked me relay through another airplane to them when I safely on the ground.

It is a long trip from 16,000 to the surface. I had lots of time to kill so I tried everything to identify the problem... No luck... it would not deliver more fuel. The fuel flow was below 3 gallons and really could barely tell the difference between the mixture forward or idle cut-off. I pulled the prop back and spiraled down over the airport.

The actual landing was a non-event. I was over the high key at 1800 AGL, did my 360 and when i had the airport made, pushed the prop up, dumped the flaps and slipped like a big dog to a landing just past my aim point on the runway.

The engine was idling, but advancing the throttle at all would kill it. I radioed to an over-flying airplane to tell center that I was safely on the ground....

It would not taxi in the grass. I pulled the mixture, it quit, I pushed the throttle up and hit the boost pump, the fuel flow went to 8 gph. I hit the starter and it fired up, ran fine and I taxied in....

I was done trying to diagnose the problem.... The servo is on the way to Air Flow Performance. I have pulled all the hoses in the fuel system. They all look good, but I will replace them because it's time. I still have no idea why it would not run...

Some will disagree with my descision to fly it to diagnose the problem. I can accept that. I can argue that after the first take-off from the farm strip, I was never in a place where I did not have a good landing option. I can argue that at that point I believed, even when it was not working, it would deliver enough fuel to fly. Still it would be pretty easy to argue that I should not have taken off from the farm strip. That is a fair criticism...

As for what is causing the problem? I am totally stumped. I hope Don finds something, or the next take-off will be no fun at all....

It may end up being connected with the painting (I hope) because the airplane was dormant or the dust in a paint shop.

If paint dust proves to be the culprit, that is pretty scary.... It could have been several more hours before the problem arose.

There is room to discuss whether I should have tried to find the problem by flying, but what this really highlights is how stupid it was to fly it home from the paint shop and land in low IMC. That flight was the flight before this problem surfaced. Had the engine started losing fuel flow in Low IMC it could have been a very different outcome.

No matter what altitude, a dead stick to a 2-300 foot ceiling is a bad deal. Even if you are directly over an airport.

I will file a report when (& if) I figure out what the problem is.....