SwissVolts

Member

Hello everyone,

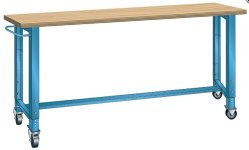

Why does everyone use wooden workbenches?

I have seen the EAA 1000 and I like it, but it seems to me that a table with height-adjustable metal legs and wheels is much easier to build and practical! Why are they not used? Maybe I'm missing something...

The idea is 3 tables at the same height that can be combined with each other. The adjustable legs solve that and when necessary they can be adjusted to different heights.

Basically it is about buying the legs and screwing the boards... For more rigidity you can install a second board below that will serve as a shelf and you can also easily hang drawers.

What is your opinion ? Thanks !

Why does everyone use wooden workbenches?

I have seen the EAA 1000 and I like it, but it seems to me that a table with height-adjustable metal legs and wheels is much easier to build and practical! Why are they not used? Maybe I'm missing something...

The idea is 3 tables at the same height that can be combined with each other. The adjustable legs solve that and when necessary they can be adjusted to different heights.

Basically it is about buying the legs and screwing the boards... For more rigidity you can install a second board below that will serve as a shelf and you can also easily hang drawers.

What is your opinion ? Thanks !