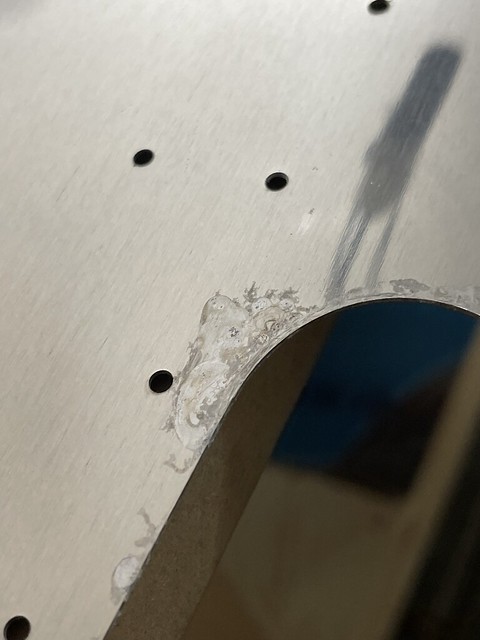

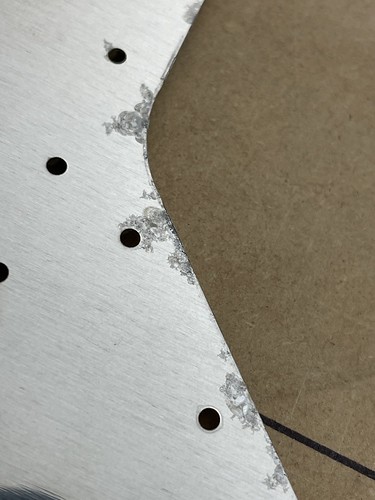

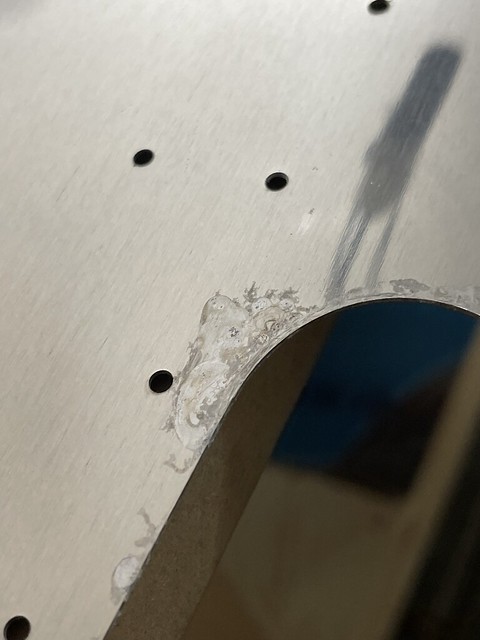

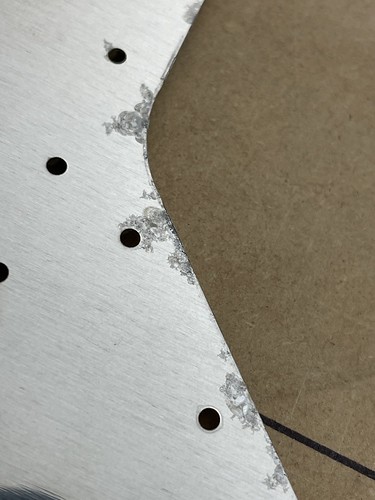

I left several sheets outside my garage for 1 month. Terrible corrosion.

Alclad doesn't protect anything.

It works just to keep the metal shine on the way from manufacture to your garage. But you will get corrosion immediately after you put your plane outside your garage.

IMG_7974 by Dozer, on Flickr

IMG_7974 by Dozer, on Flickr

IMG_7975 by Dozer, on Flickr

IMG_7975 by Dozer, on Flickr

IMG_7978 by Dozer, on Flickr

IMG_7978 by Dozer, on Flickr

IMG_7977 by Dozer, on Flickr

IMG_7977 by Dozer, on Flickr

Alclad doesn't protect anything.

It works just to keep the metal shine on the way from manufacture to your garage. But you will get corrosion immediately after you put your plane outside your garage.

IMG_7974 by Dozer, on Flickr

IMG_7974 by Dozer, on Flickr IMG_7975 by Dozer, on Flickr

IMG_7975 by Dozer, on Flickr IMG_7978 by Dozer, on Flickr

IMG_7978 by Dozer, on Flickr IMG_7977 by Dozer, on Flickr

IMG_7977 by Dozer, on Flickr

Last edited: