sinflrobot

Member

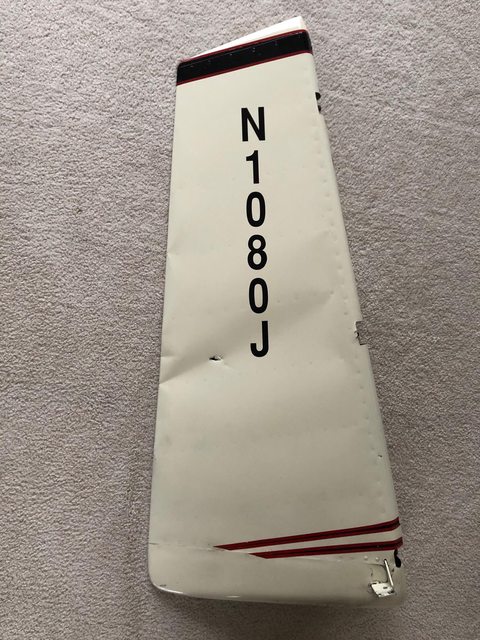

Some wind got a hold of my rudder during the last front that came through. Overall it still appears straight, but I am a bit concerned about what to do with two small tears in the trailing edge. It doesn't look horrible, but I was wondering what more experienced folks think the best way to repair this is.

(Its an RV6A, so it doesn't have the riveted in trailing edge wedge.)

(Its an RV6A, so it doesn't have the riveted in trailing edge wedge.)