wirejock

Well Known Member

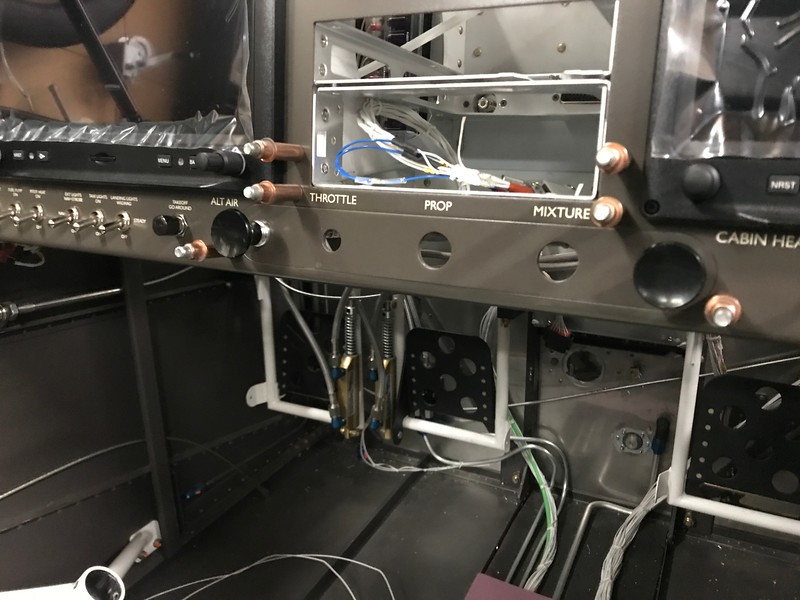

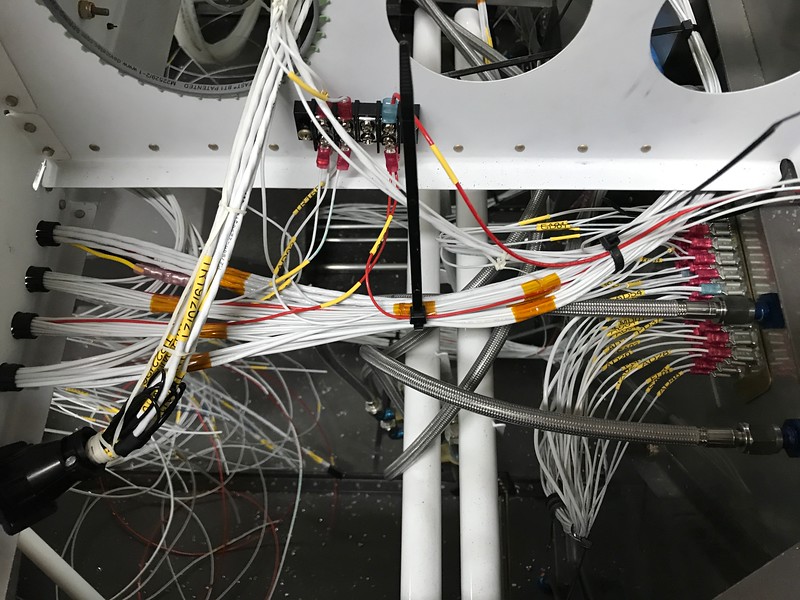

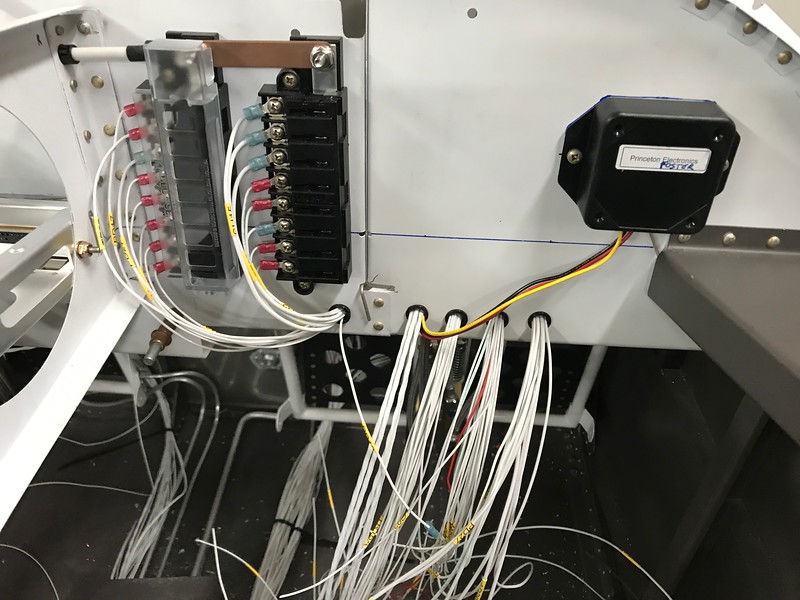

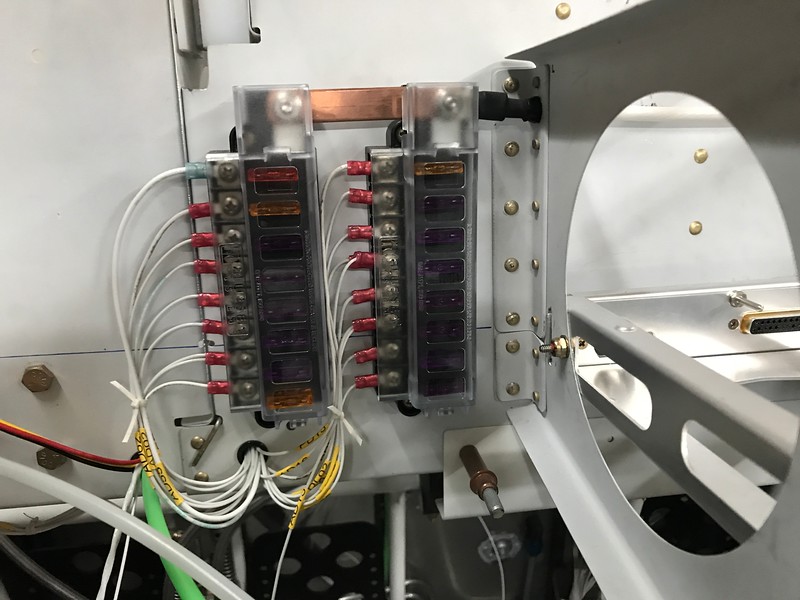

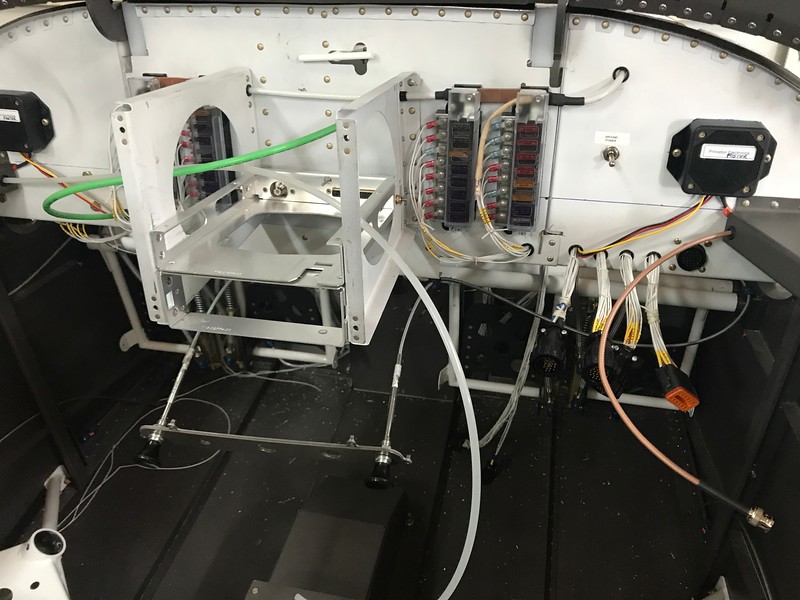

This thread is about all the cables going from the avionics bay to everywhere else. I made a list with conductor/size or manufacturer's designation. There's a lot. List is below

First question

I see OP-30 shows wire going up the tunnel then up the firewall tunnel and back. I've also seen wire going up the F-902 Bulkhead. What route did you take?

Second question

I have this document. Do I interpret the drawing correctly? One hole may be drilled in each bay? Potentially four holes total?

List. The ACM requires individual runs for the servos and ADAHRS so no hub.

Com,coax

Xponder,coax

ADSB,coax

Wing Tip left, 18/2 (Land/Taxi), 22/3 (Strobe/Pos)

Wing Tip right, "

Tail strobe, 22/2

Stall switch, 18/1

Sticks, ACM cable

Boost pump, 18/1 red, 18/1 Blk

Roll Servo, Dynon network cable

Pitch Servo, Dynon network cable

ADAHRS, Dynon network cable

Pitch Trim, Ray Allen cable

Roll Trim, Ray Allen cable

ELT, 22/3

First question

I see OP-30 shows wire going up the tunnel then up the firewall tunnel and back. I've also seen wire going up the F-902 Bulkhead. What route did you take?

Second question

I have this document. Do I interpret the drawing correctly? One hole may be drilled in each bay? Potentially four holes total?

List. The ACM requires individual runs for the servos and ADAHRS so no hub.

Com,coax

Xponder,coax

ADSB,coax

Wing Tip left, 18/2 (Land/Taxi), 22/3 (Strobe/Pos)

Wing Tip right, "

Tail strobe, 22/2

Stall switch, 18/1

Sticks, ACM cable

Boost pump, 18/1 red, 18/1 Blk

Roll Servo, Dynon network cable

Pitch Servo, Dynon network cable

ADAHRS, Dynon network cable

Pitch Trim, Ray Allen cable

Roll Trim, Ray Allen cable

ELT, 22/3

Last edited: