AndyRV7

Well Known Member

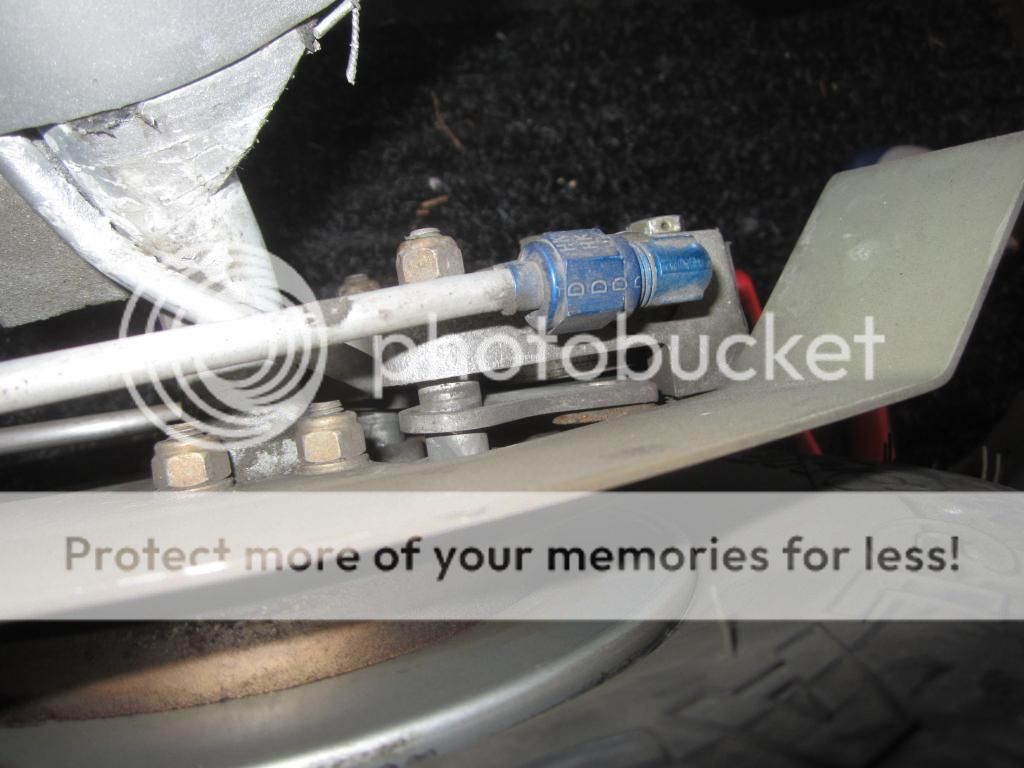

I was hoping someone could help me understand the brake calipers/system. I am trying to understand what keeps the caliper centered around the rotor. The whole caliper floats on the 2 dowels of sorts but what keeps the pads from dragging constantly on the disk or from contacting the disk at an angle?

I read in one of the threads that you want to be sure not to have any "preload" of sorts on the caliper from the brake lines. So how do you know if there is any odd pressure on the caliper when it floats relative to the disk.

Thanks! Andy

I read in one of the threads that you want to be sure not to have any "preload" of sorts on the caliper from the brake lines. So how do you know if there is any odd pressure on the caliper when it floats relative to the disk.

Thanks! Andy