Roadjunkie1

Well Known Member

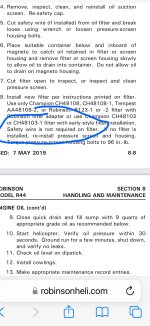

I have one I used on Tempest and Champion filters. I like it; easy way to do proper torque for those. Torques to 17ft/lb. Won't work on the reusable filter fitting but there is plenty of room on a -4 for the torque fitting and wrench.Maybe room if you used one of these.

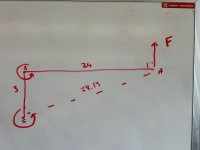

Would a 'crow's foot' work back there? I use one on my prop nuts as a regular torque wrench won't fit. You have to figure out the math as to how much that extra length is changing the indicated torque value.