Saville

Well Known Member

Hi all,

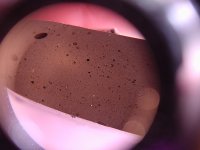

I have a few paint bubbles around some upper wing rivets. Some of them broke - others will soon. There is bare aluminum where the bubbles broke.

What I want to do is remove the loose paint, do whatever has to be done for priming, and repaint the small areas, feathering in the paint so that there won't be obvious old paint perimeters.

But I have a few questions:

1) How do I remove the loose paint until I get to paint with solid adherence without damaging the aluminum?

2) Should I alodine the area? (I believe I need to but I want to check).

3) Will the alodine lift more paint?

4) How can I prime and paint the area and feather in the old paint so that the bubble perimeter does not show?

Thanks for any tips you may have.

I have a few paint bubbles around some upper wing rivets. Some of them broke - others will soon. There is bare aluminum where the bubbles broke.

What I want to do is remove the loose paint, do whatever has to be done for priming, and repaint the small areas, feathering in the paint so that there won't be obvious old paint perimeters.

But I have a few questions:

1) How do I remove the loose paint until I get to paint with solid adherence without damaging the aluminum?

2) Should I alodine the area? (I believe I need to but I want to check).

3) Will the alodine lift more paint?

4) How can I prime and paint the area and feather in the old paint so that the bubble perimeter does not show?

Thanks for any tips you may have.