I filled my tanks to full this week to calibrate some things and found fuel leaking out the fuel vent. At first I thought this was an overflow situation down the vent line, but after some taxi testing and a few days of drips, the fuel level is low enough that the end of the vent is dry and above the fuel level.

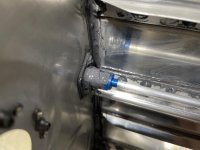

There is no fuel outside the tank anywhere, just a steady slow drip out the vent line. The only thing I can figure it must be is a loose or leaking fitting inside the tank, where the vent tubing connects to the blue AN fitting that passes through the tank wall.

Other than “don’t fill the tanks above 20 gallons and park the plane”, does anyone have any advice how to fix this? I don’t see any way to get a wrench in there to tighten that fitting. And how dangerous is this? If this came loose in flight, all the gas above that line would dribble out, although I guess some suction through the vent as gas is burned would slow the drip rate.

My tanks were quick build tanks, for what that’s worth.

Thanks in advance!

There is no fuel outside the tank anywhere, just a steady slow drip out the vent line. The only thing I can figure it must be is a loose or leaking fitting inside the tank, where the vent tubing connects to the blue AN fitting that passes through the tank wall.

Other than “don’t fill the tanks above 20 gallons and park the plane”, does anyone have any advice how to fix this? I don’t see any way to get a wrench in there to tighten that fitting. And how dangerous is this? If this came loose in flight, all the gas above that line would dribble out, although I guess some suction through the vent as gas is burned would slow the drip rate.

My tanks were quick build tanks, for what that’s worth.

Thanks in advance!