Our engineering team is reviewing the manufactured parts shipped as part of SB-00036 and has issued a revision to those parts due to an unanticipated potential fatigue issue that was just discovered. As a result, we have placed all pending shipments on hold until that process has been completed. We have also published

SB-00036 REV1, which includes the inspection steps but has the steps related tp installation of the new hinge brackets removed (we will update with new instructions once the new parts are ready). It also includes information outlined in this post.

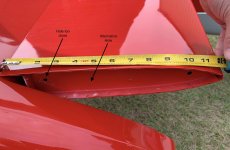

We've sent an email notification to customers who were already shipped SB-00036 kits. Those kits contain replacement outboard elevator hinge brackets for RV-4/6/7/8 aircraft. We are also emailing all builders who received the newer hinge brackets in their RV-7 and RV-8 tail kits in late 2022 and January 2023.

Builders/owners who have received these parts but have not yet installed them are advised to hold off on installation and wait for replacement parts. If you have installed them on a flying airplane, you may continue to operate the aircraft until the revised parts are available, at which time they will need to be replaced.

If you ordered the SB kit but have not yet received a shipment notification from Van's, know that we have placed your order on hold until the new parts are available. A kit with the new parts will ship to you automatically as soon as they have been manufactured and received. For those who have not already, you can also pre-order the SB kits on the Van's web store, and they will be shipped as soon as the new parts are available.

Van's is prioritizing the production of these new parts and we will strive to ship the replacement parts as soon as possible.

We recognize and apologize for the trouble this unexpected revision creates for builders and owners who have already received - and in some cases installed - the problem parts, and the delays shipping to those with parts on order. We take the revision process very seriously. Due to the potential fatigue issue with the affected parts it was deemed necessary to replace them.

We will communicate with affected customers via email and - of course - here on VAF about this in the next several business days, once we have a timeframe established for the revised parts.