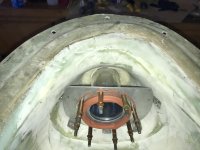

I've been trying to implement a leak free connection between front cowl and airbox using some of the ideas in this thread. My lower cowl snout is separately removable so it can be slid on to the cowl using a horizontal front-to-back motion. My thought was to attach a flexible hose to the lower cowl snout and it would fit into a closely shaped duct on the front of the FAB.

My first attempt used a 2.75" SCAT tube (wire removed for flexibility) that was clamped onto the snout. No pictures because cause it is too rough, and I had trouble getting good alignment between the two parts which would cause the tube to be wrinkled.

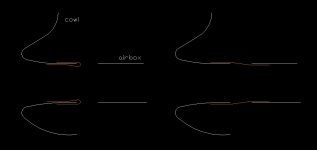

My question is - is 2.75" too small? The cowl snout inlet is about 4.25 x 2.2 inches, but with large radius corners, so something under 9 in2, maybe 8 in2? A 2.75" SCAT is only about 6 in2. Going up to 3" SCAT increases the area to 7 in2.

So my question is: does it matter? I don't want to go thru all this work and make a restrictive inlet.

I was wondering if going round was a dumb idea... maybe stick with a more rectangular shape on the flexible duct/sock.